Last Mile Delivery Drivers And Package Handlers Work Safer And Effortlessly

Eliminate The Biggest Safety Risk with Active Random Loading

The GHE Solution enhances safety by introducing a new loading method for delivery vehicles called Active Random Loading. This method allows pre-loaders to load packages in any order without depending on numbered segments or sticker systems. Active Random Loading allows pre-loaders to place heavy packages on the bottom layer of the delivery vehicle and lighter packages on top. This eliminates the biggest safety risk to pre-loaders and drivers, which is caused by heavy packages on the top layer shifting during transit. By eliminating manual sorting and reducing errors associated with heavy lifting, Active Random Loading not only enhances worker safety but also streamlines the pre-loading process.

Stop Wasting Time, Start Delivering Smarter

Stop wasting time on tedious and repetitive tasks. Pre-loaders shouldn't spend valuable minutes sorting packages into exact segments. Drivers shouldn't have to search packages through cluttered vans or struggle to find delivery addresses.

The innovative GHE solution enables pre-loaders to load packages randomly, eliminating the need for manual sorting. For drivers, the GHE solution significantly reduces the time wasted searching for packages and addresses by providing smart, location-aware alerts. Packages are quickly identified at the correct stop, making every delivery safer, less complicated, and more accurate.

Eliminate Time Waste Across Your Last-Mile Workflow

By eliminating the time wasted in pre-loading and package delivery, your team can load vehicles for delivery in fewer steps, deliver packages more accurately, and complete more stops per shift. Our solution helps loaders and drivers deliver the correct package to the right door the first time, removing guesswork and unnecessary backtracking.

The Space-Segment Pre-loading Method and Delivery Operations Waste Drivers’ Time and Also Pose Safety Risks

Safety Hazards

Now, heavy packages must be loaded onto the top shelf of the delivery vehicle in order and then frequently reorganized. These tasks not only waste workers’ time and physical energy but also pose significant safety risks, including sprains, strains, and other injuries among pre-loaders and drivers. Such injuries contribute to tens of thousands of workplace accidents each year.

Time-Consuming

Last-mile delivery companies can't make as many customer deliveries as they should because their drivers spend too much time searching for packages and door numbers rather than delivering packages.

Now, the heavy packages need to be lifted to the top layer shelves of the vehicle, and they must be frequently organized on the top layer. These operations not only waste workers’ time and energy but are also the biggest safety hazards that cause various injuries, such as sprains and strains, to pre-loaders and drivers, resulting in tens of thousands of safety accidents every year.

A study we conducted, involving more than 200 on-site tests of last-mile delivery operations, found that during pre-load at delivery stations, 70% of the time is wasted on orderly, segmented package placement. More than 50 percent of a driver's time is spent searching for packages and door numbers in express and last-mile delivery.

Lost Time, Lost Profit

Most delivery time is wasted on two activities: searching for packages inside the van and locating customer addresses. During the day, drivers spend extra time searching for the correct packages. At night, they spend additional time searching for drop-off destinations, especially in mountainous areas, which reduces the effective work time to below 20 percent.

Because last-mile delivery accounts for nearly half of e-commerce logistics costs, wasting drivers’ time with the current method leads to safety risks and smaller profit margins.

How Heart Yang Came up With the Idea for the GHE Solution

After tech entrepreneur Heart Yang emigrated from China to the United States under a special visa for aliens with extraordinary ability, he worked as a delivery driver and sorter to gain a deeper understanding of the American logistics industry. In his home country, Yang conducted pioneering work in the Internet of Things (IoT) and worked as a consultant in logistics and express delivery technology for 15 years.

As a seasonal support driver (SSD) and a sorter for a major parcel company, Yang found himself three times more productive than regular drivers. His higher productivity stemmed in large part from his photographic memory that enabled him to spend less time on:

Pre-load

Pre-loading packages into the corresponding segments in order

Place

Placing packages into their designated containers

Search

Searching for packages and delivery confirmation stickers

Locate

Using navigation to locate delivery addresses

Look

Finding the correct delivery doors

Return

Making fewer return trips to the same delivery location or neighborhood.

Knowing that most people don’t have photographic memories, Yang realized that technology would have to assist drivers in finding a package and door’s location. The GHE solution he devised enables quick location finding with its combination of IoT devices and cloud-based artificial intelligence (AI.)

Last Mile Delivery Industry Status

Ordered Loading

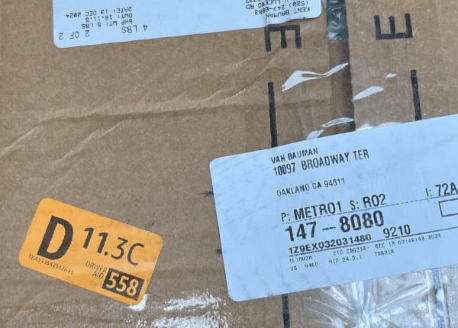

Place the package into the corresponding segment according to the numbers on the sticker. If there are already packages in that segment, it is necessary to reposition the existing packages so that this new package can be inserted into the correct order.

Look Around for the Location of the Delivery Confirmation Sticker

Although the sticker confirmation process takes only a few seconds, it must be repeated for every single package. When all of those seconds are added up over the work shift, the amount of time wasted on searching for packages is astounding.

Improper Delivery Confirmation Stickers Are Often the Root Cause of Package Searching

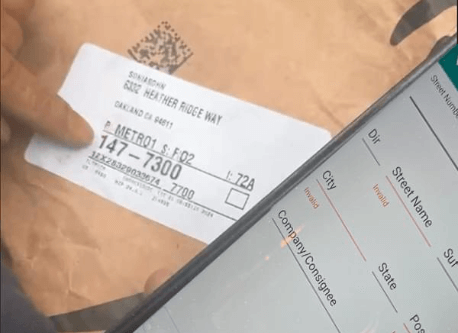

Yang’s experience as a driver also led him to conclude that misapplied and improper Delivery Confirmation Stickers - termed “mis-sticking” - are one of the main reasons workers wastes time searching for the correct delivery item.

The Overlooked Industry Problem of Delivery Confirmation Stickers

In Yang’s view, the extent of the problem with sticker mis-sticking in the delivery industry was greater than most companies realized. He concluded that:

* The combined rate of package mis-sticking and mis-loadings affects more than 2% of all daily delivery shipments.

* Incidents of mis-sticking interfering with delivery occur more frequently than are reported to management.

Locate the House Number Plate and Make Out the Blurry Numbers

Existing house number plates often use small fonts and are typically printed in black. They are also frequently covered by flowers, trees, trash cans, or parked vehicles. At night, the numbers are challenging to see clearly. Sometimes drivers even have to push aside branches and turn on flashlights to see them. This not only increases the difficulty of their work but also wastes valuable delivery time, leaving drivers feeling anxious and stressed.

The Problem of Package Shifting

Yang also found another reason drivers waste time searching for packages: when a delivery driver makes a sharp turn or brakes suddenly, the packages often shift in the van’s load space. Remembering the original package location is no help if the items in the cargo bay have been thrown into disarray.

Yang realized that any solution to eliminate package searching must address both cargo-bay shifting and mis-sticking, while also providing a memory aid for locating packages within the van’s load space.

The GHE Solution

Eliminating the time spent on searching for packages speeds up delivery, reduces a driver’s mental and physical fatigue while making the work easier and safer.

Time to Find

Traditional Solution

Delivery Confirmation Sticker

- Searching Around Van

- Scanning Sticker

- Sticker Damage or Mislabeled Items

- Time-consuming

- Inefficient

- Consumables

- Paper Waste

Time to Locate

GHE Smart Solution

Wireless Light Tag

- Smart Tag

- Audio and Visual Identification

- Time-saving

- Effortless

- Efficient

- Reusable

- Paperless & Eco-friendly

Time to Find

Traditional Solution

All kinds of personalized doorplate

- Searching Around

- Time Consuming

- Inefficient

- Consumables

Time to Find

GHE Smart Solution

Smart House Number Plate

- Visual identification

- Time-saving

- Certificate of the package to the destination

- Humanized

|

Pre-Loader Actions |

Classification |

Traditional

Solution |

GHE

Paradigm |

|---|---|---|---|

|

Sorting packages on the assembly line Scan the barcode on the packages and move into the vehicle Scan the barcode on wireless light tags and binding to package |

1 * 1 * 2 * |

2~3s 10s 0 |

2~3s 10s 2s |

|

Looking for a designated segment in the vehicle while carrying package Require guesswork and judgment if the segment numbers are unclear Lift heavy packages to the top shelves (lead to tens of thousands injures) Frequently organize package in order (lead to so many injures) Write big number on the package or re-stick the stickers Retrieve the package for the vehicle at the end of the assembly line Frequent viewing and operation of wearable computer Frequent reconnect the Ring Scanner to wearable computer Subsidy sticker if there is no sticker on the package |

2 * 2 # 2 # 2 * 2 * 2 # 3 * 3 2 |

10s 20s 10s 10~30s 10s > 60s 5s > 120s > 60s |

0 0 0 0 0 0 0 0 0 |

Definition of classification numbers

1 = The action meet the first principles

2 = The action only is fighting against the law of entropy increase or convenient driver to retrieval packages

3 = The cation is caused by hardware or engineering

* = Means each package need this action

# = Means a part of packages need this action

|

Driver Actions |

Classification |

Traditional

Solution |

GHE

Paradigm |

|---|---|---|---|

|

Drive to destinations Grab packages and move them to customers' doorstep |

1 * 1 * |

X X |

X X |

|

Recycle the wireless light tag |

2 * |

- |

1s |

|

Scan barcode & take a photo Retrieval the package in the vehicle after each stop Frequent viewing and operation of work phone Organize the packages 3~8 times daily according to different areas Removing & organize packages on the top shelf (causing a lot of damage) Wasted trip because of packages are not loaded into vehicle Multi round-trip because of wrong pasted stickers Multi round-trip time caused by Service Division Multi round-trip time caused by not finding the package in time Write big numbers on all packages Various difficult situations caused by lack of cell phone signal Work phone can't scan the barcode, crashing and restarting Repair damaged packages that were dropped from top shelves Waste long time to retrieval the package with wrong big number Waste long time to confirm which stickers is today's? (Multiple stickers package) |

1 * 2 * 2 * 2 * 2 # 2 2 2 2 2 * 3 3 2 2 2 |

X 10~600s 10s 300~2000s/time X 180~600s Immeasurable Immeasurable Immeasurable 10s Immeasurable Immeasurable 30~60s 10~600s > 30s |

X 0 0 0 - 0 0 0 0 0 0 0 0 0 0 |

Definition of classification numbers

1 = The action meet the first principles

2 = The action only is fighting against the law of entropy increase or convenient driver to retrieval packages

3 = The cation is caused by hardware or engineering

* = Means each package need this action

# = Means a part of packages need this action

Wireless Light Tag

The GHE solution provides smart tags that make it possible for a driver to locate the correct package in a crowded cargo bay in one second.

Each package is equipped with a wireless light tag. The tags are applied at the last-mile delivery station so the driver can focus on the task of delivery.

Wearable Computer

Drivers carry a wearable computer that activates the tag for fast identification. The tags on the package required for a specific customer delivery will flash and beep so the driver can quickly grab the correct item instead of wasting time searching the vehicle.

Eliminating the time spent on searching for packages speeds up delivery, reduces a driver’s mental and physical fatigue, and also makes the work easier and safer.

Operation Process

The GHE Solution

simplest Process for preloaders

Step 1:

Scan the package barcode. Next, scan the wireless light tag and attach it to the corresponding package. The wearable computer will automatically upload the delivery information for each package linked to a wireless light tag.

Step 2:

Load the scanned packages into the vehicle. Wireless smart tags allow packages to be loaded in any order. Begin by placing the heaviest packages on the bottom layer, the lightest on top, and all others on the middle layer of the vehicle.

The GHE Solution

simplest Delivery Process for drivers

Step 1:

Drive to the delivery destination. When the van stops at the customer drop-off, the intelligence system detects the halt,all deliverable packages automatically light up. This visual cue helps drivers avoid missed deliveries and unnecessary round-trips.

Step 2:

Directly grab the package to be delivered, deliver it to the customer's door, and take a photo. Return to the vehicle and start the next stop until all packages are delivered.

GHE Provides These Benefits