The Paradigm Shift: Why Every Physical Industry Must Stop Fighting Entropy.

24 Dec, 2025

At GHE Solution, we believe the primary obstacle to economic growth is the cost of managing Information Entropy, defined as the rate at which a system's disorder renders its data unreliable.

The faster the disorder, the more time, energy, and human cognitive capacity that gets wasted by traditional "Entropy Control" methods (i.e., manual scanning, mental calculations, searching). This is why the social value and ROI of adopting an Embrace Entropy model, in which chaos is managed by ultra-low-power IoT + AI, are highest in systems that fail the fastest.

Our extensive research prioritizing operational overhaul led to this ranking, demonstrating where the need for this cognitive and technological shift is most critical:

GHE's Priority Ranking: Rate of Information Entropy Increase

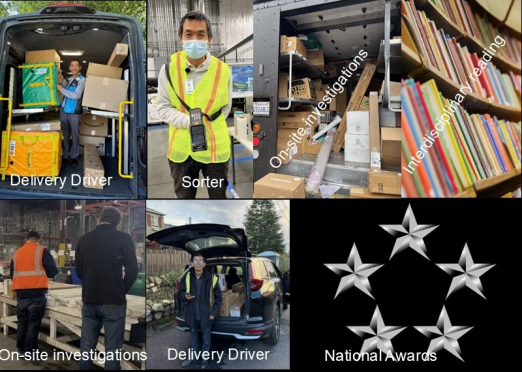

- Last-Mile Delivery (In-Vehicle): Extreme kinetic chaos (sharp turns, sudden stops) rapidly randomizes packages inside the vehicle.

- Last-Mile Station Manual Sorting and loading: Human cognitive limits in memorizing hundreds of delivery addresses forces inefficient, multi-step sorting processes.

- High-Density Piece Picking: Frequent human-machine interaction in narrow aisles leads to constant misplacement and orientation errors, rapidly eroding inventory accuracy.

- LTL Cross-Docking: High volume of mismatched, often irregular cargo handled in a single transaction, leading to rapid co-mingling chaos.

- Emergency Response & Disaster Logistics: Instantaneous demand spikes combined with destroyed infrastructure creates peak, immediate chaos.

- Construction & Site Logistics: Highly dynamic sites with constant movement of temporary materials, tools, pipeline & cable information and shared resources.

- Grocery & Fresh Food: High time-sensitivity compounded by extreme SKU volatility (promotions/seasonality) and complex store-level operations/returns.

- Hospital & Clinical Supply: High-value, life-critical materials (drugs, blood) moving across disparate departments under rigid compliance rules.

- Field Services & Utilities Maintenance: Dispersed assets and constantly changing on-site conditions make work order tracking and material preparation inherently chaotic.

- Apparel / Fast Fashion Retail: High return rates and rapid SKU turnover create a persistent sorting and matching nightmare (Reverse Logistics).

- Agriculture Harvest & Distribution: Geographically vast, time-critical operations with unpredictable yield/quality variability.

- Job-Shop / Custom Manufacturing: High product diversification mandates complex, one-off material tracking for every order.

- Automotive Aftermarket & Spare Parts: Massive SKU proliferation and the complexity of part compatibility/versioning.

- Vehicle Final Assembly: Standardized process, but still prone to part misplacement.

The opportunity is clear: The industries at the top of this list are where the traditional manual effort is failing fastest. This is also where GHE's ultra-low-power, high-precision IoT + AI solutions can deliver multi-fold efficiency gains by allowing chaos to be managed digitally, not manually. We are turning the most chaotic scenarios into the most efficient.